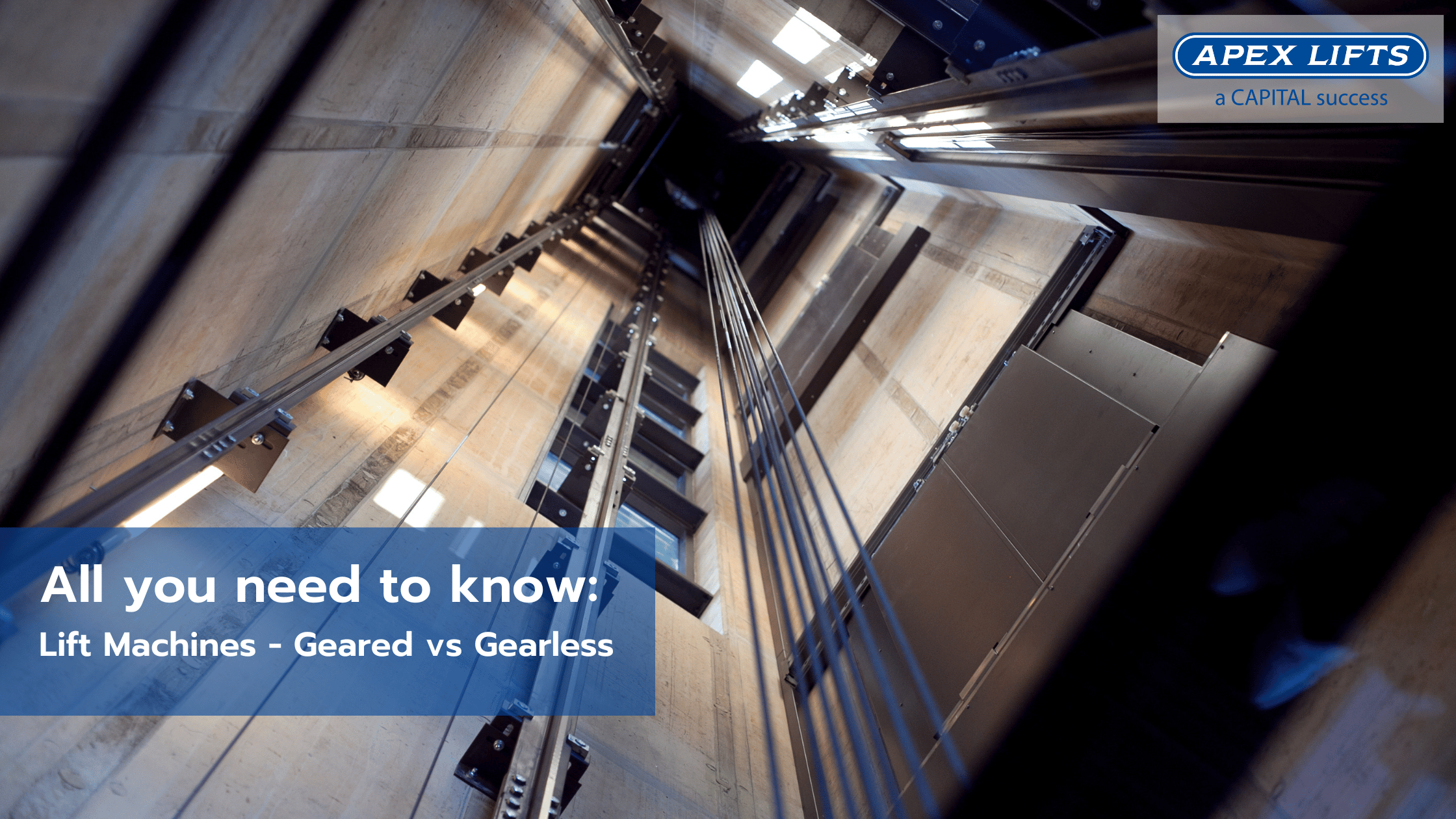

The choice between a geared and gearless traction lift is a question that most construction teams are faced with on their projects. Although from afar it may seem one entirely outweighs the other, there is an abundance of variables that may affect this decision. Such as the costs involved, initial desire, and of course suitability to the project. When faced with the daunting question of what to go with, it is a great idea to list out the benefits and limitations of each lift machine.

The most significant deviation between a gearless and geared lift is the machine room. Widely known as MRL lifts, (machine-room-less) gearless lifts benefit from being a space-saving alternative to a geared lift. Juxtaposed to a geared lift to which requires a machine room in order to be able to securely mount the sheave and motor, above or adjacent to the lift shaft itself.

With this in mind, the placement of the machine room must be carefully considered during the planning stages of a building’s design, thus creating more work in the short term. Due to the size and equipment required, geared lifts can often be seen as a significant space intruder when building within boundaries and often present a substantial drawback in uptake on new installations.

Equally, when it comes to energy efficiency, gearless motors often exceed expectations. Due to the reduced size of gearless motors, they often outperform the likes of a geared motor. In turn, reducing electricity usage. This is largely due to them being a more efficient product with reduced frictional losses which can increase both performance and longevity, thus becoming the more appealing option.

Adding to the desirability of a gearless lift is its move rate. Typically, a gearless lift can move passengers a lot faster than that of a geared lift. Although, that is not to say that a geared traction is incapable, as both geared and gearless lifts have similar load capacity for passenger travel. However, for distance and speed, a gearless lift quite clearly outweighs the benefits of a geared lift.

However, as with most technologies come problems. A clear and substantial factor to both traction types is their repair. Although easier and somewhat cleaner, gearless lifts require less routine maintenance. This is widely due to the fact that gearless lifts don’t require grease and have significantly less moving parts and bearing. Whereas geared lifts have multiple, making maintenance of the lift more frequent and costly.

Additionally, being comprised of such large-scale components, geared lifts require more specialised tools to do the job which can often make maintenance more difficult. As well as the long-term cost involved too. That being said, finding the right lift machine for your project will comprise of a variety of decisions, maybe such as the pros and cons listed above. However, if the cost be one of them, then the geared lift is sure to reduce those, but in turn, also reduces efficiency and increases maintenance costs. To which it then begins a question of efficiency or cost that concludes that final decision.